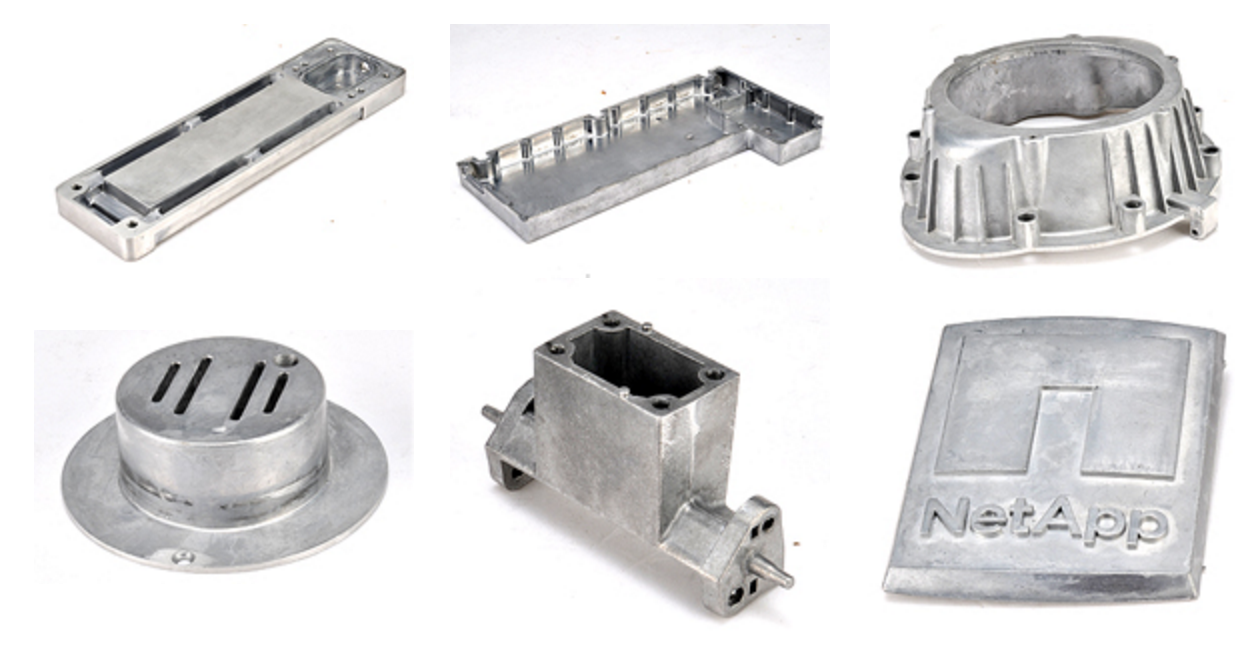

Fit Mould manufacture and maintain a number of tools for both Aluminum and Mazak material for a number of foundries, the design process and tool complexity are very similar to the Plastics industry with a lot of the CAD requirements being the same, all the tools need a feed system, a cooling/heating system, and ejection to get the product out of the tool so the synergy is there from design to completed component.The process of die casting is quite harsh on the tools with some foundries offering a reduced life span on the tooling before major repair work is required, Mazak a zinc based alloy which is much heavier than Alminum and is processed at much lower temperatures is favoured by a lot of companies the tooling is of similar construction, but the feed gates and sprue (area where the Mazak comes into the tool, and on to the component cavity) are of a different configuration.

Fit Mould pressure die-casting division offer a range of fully automated machines from 200 to 1200 tons locking force for weight to 10-15kg components, Rich experience has enabled us to consistently produce the high quality products for our customers.Our main die-casting parts include auto and motorcycle engine cases, covers, starters, alternators, clutches, drive faces, and hardware tools.

Material:

Aluminum Alloy, Zinc Alloy, Magnalium.

Second operation:

CNC Machining, Polishing, EDM Texture, Turning, Sand Blasting, Tapping.

Lacquer, Electro-Deposited Coating, Chrome Plating, Nickel Plating.

Nodinson die-casting advantage:

Cost-effective production

Cost-effective design

Tight dimensional tolerances

Thin wall construction

Good physical properties